The Indelible Mark of Precision: Unveiling the Power of Diamond-Tipped Tools

Related Articles: The Indelible Mark of Precision: Unveiling the Power of Diamond-Tipped Tools

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Indelible Mark of Precision: Unveiling the Power of Diamond-Tipped Tools. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: The Indelible Mark of Precision: Unveiling the Power of Diamond-Tipped Tools

- 2 Introduction

- 3 The Indelible Mark of Precision: Unveiling the Power of Diamond-Tipped Tools

- 3.1 Understanding the Significance of Diamond-Tipped Tools

- 3.2 Unveiling the Advantages of Diamond-Tipped Tools

- 3.3 Understanding the Types of Diamond-Tipped Tools

- 3.4 Choosing the Right Diamond-Tipped Tool

- 3.5 FAQs on Diamond-Tipped Tools

- 3.6 Tips for Using Diamond-Tipped Tools

- 3.7 Conclusion

- 4 Closure

The Indelible Mark of Precision: Unveiling the Power of Diamond-Tipped Tools

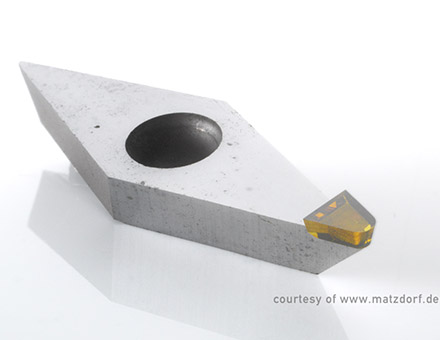

In the realm of precision engineering and craftsmanship, the pursuit of accuracy and durability is paramount. Tools, the instruments of creation, often bear the brunt of this pursuit, constantly striving to deliver flawless results. Among these tools, a unique class stands out, marked by an unparalleled sharpness and resilience – tools with diamond-tipped working surfaces.

Diamond, the hardest naturally occurring mineral, possesses an exceptional combination of properties that make it ideal for crafting tools that demand unwavering precision and longevity. Its remarkable hardness ensures a sharp, consistent cutting edge that resists wear and tear, maintaining its cutting power over extended use. This translates to consistently accurate and precise results, a crucial factor in industries where tolerances are measured in microns.

Understanding the Significance of Diamond-Tipped Tools

The applications of diamond-tipped tools span diverse industries, each relying on the unique benefits these tools offer:

1. Manufacturing and Engineering:

- Machining: Diamond-tipped tools are indispensable in machining operations, particularly for materials known for their hardness and wear resistance. These include metals like hardened steel, titanium, and ceramics, where conventional tools struggle to achieve precise cuts.

- Drilling: Diamond-tipped drill bits excel in drilling through hard and abrasive materials, maintaining accuracy and speed even in challenging conditions. They are used in various applications, from drilling into concrete and rock to creating precise holes in glass and other delicate materials.

- Turning: Turning operations involve removing material from a rotating workpiece, shaping it to a desired form. Diamond-tipped tools are crucial for turning hard materials, ensuring smooth, accurate cuts and a superior surface finish.

- Milling: Diamond-tipped milling cutters are widely used in the manufacturing of complex components, enabling the creation of intricate shapes and precise features with exceptional accuracy.

2. Construction and Infrastructure:

- Concrete Cutting: Diamond-tipped saw blades and core drills are essential for cutting and drilling through concrete, providing clean, accurate cuts and reducing the risk of damage to surrounding structures.

- Road Cutting: Diamond-tipped tools are employed in road construction and maintenance, ensuring precise cuts for road expansion, repairs, and the creation of drainage systems.

- Tunnel Boring: Diamond-tipped tunnel boring machines (TBMs) are crucial for excavating tunnels, effectively cutting through rock and soil with minimal disruption to surrounding areas.

3. Electronics and Semiconductor Industries:

- Wafer Processing: Diamond-tipped tools play a critical role in the semiconductor industry, used for wafer dicing, scribing, and other precision operations, ensuring the creation of high-quality semiconductor devices.

- Circuit Board Manufacturing: Diamond-tipped tools are used for cutting, drilling, and routing circuit boards, enabling the production of complex electronic components with intricate circuitry.

4. Jewelry and Gemstone Cutting:

- Diamond Cutting: Diamond-tipped tools are essential for cutting and polishing diamonds, ensuring the creation of brilliant and flawless gemstones.

- Gemstone Faceting: Diamond-tipped tools are used for faceting other gemstones, creating intricate patterns and maximizing their brilliance.

5. Scientific Research and Analysis:

- Microscopy: Diamond-tipped probes are used in microscopy, enabling the manipulation and analysis of materials at the nanoscale level.

- Materials Science: Diamond-tipped tools are employed for cutting and preparing samples for analysis, ensuring accuracy and preserving the integrity of the materials under investigation.

Unveiling the Advantages of Diamond-Tipped Tools

The utilization of diamond-tipped tools brings several advantages to various industries:

- Exceptional Hardness and Durability: Diamond’s exceptional hardness ensures the cutting edge remains sharp and resistant to wear, allowing for extended tool life and consistent performance. This translates to increased productivity and reduced downtime due to tool replacement.

- Precision and Accuracy: The sharp, consistent cutting edge of diamond-tipped tools enables precise and accurate cuts, crucial for achieving tight tolerances and producing high-quality components. This accuracy is vital in industries where even minute deviations can impact performance and functionality.

- Versatility: Diamond-tipped tools can be used on a wide range of materials, from hard metals and ceramics to glass and composites. This versatility makes them valuable assets across diverse industries, offering a single solution for multiple applications.

- Increased Efficiency: The superior cutting performance of diamond-tipped tools enables faster machining speeds and improved material removal rates, leading to increased productivity and reduced production time.

- Reduced Material Waste: The precision and accuracy of diamond-tipped tools minimize material waste during machining operations, promoting efficient resource utilization and reducing environmental impact.

- Improved Surface Finish: Diamond-tipped tools produce smoother and more consistent surface finishes compared to conventional tools, enhancing the aesthetics and functionality of finished products.

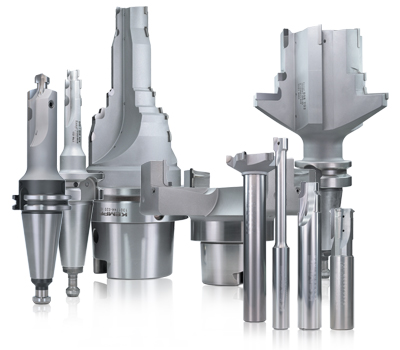

Understanding the Types of Diamond-Tipped Tools

Diamond-tipped tools come in various forms, each designed for specific applications:

- Diamond-Tipped Drill Bits: Used for drilling into hard and abrasive materials, these bits are available in various sizes and configurations to suit different applications.

- Diamond-Tipped Saw Blades: These blades are used for cutting through concrete, stone, and other hard materials, providing clean and accurate cuts.

- Diamond-Tipped Milling Cutters: Used for machining complex shapes and precise features, these cutters are available in various designs and configurations to suit specific applications.

- Diamond-Tipped Turning Tools: Used for turning hard materials, these tools ensure smooth, accurate cuts and a superior surface finish.

- Diamond-Tipped Core Drills: These drills are used for creating precise holes in concrete and other hard materials, providing clean and accurate cuts.

- Diamond-Tipped Grinding Wheels: These wheels are used for grinding and polishing hard materials, providing a smooth and consistent surface finish.

Choosing the Right Diamond-Tipped Tool

Selecting the appropriate diamond-tipped tool for a specific application is crucial for achieving optimal performance and ensuring tool longevity. Several factors influence this choice:

- Material to be Cut: The hardness and abrasiveness of the material being cut will determine the type of diamond-tipped tool required.

- Cutting Operation: The specific cutting operation, such as drilling, sawing, milling, or turning, will dictate the type of tool needed.

- Desired Cutting Speed: The desired cutting speed will influence the size and configuration of the diamond-tipped tool.

- Cutting Depth: The depth of the cut will determine the length of the diamond-tipped tool.

- Tool Life: The expected tool life will influence the quality and concentration of diamonds on the tool’s working surface.

FAQs on Diamond-Tipped Tools

1. What are the advantages of using diamond-tipped tools?

Diamond-tipped tools offer several advantages, including exceptional hardness and durability, precision and accuracy, versatility, increased efficiency, reduced material waste, and improved surface finish.

2. What are the different types of diamond-tipped tools?

Diamond-tipped tools come in various forms, including drill bits, saw blades, milling cutters, turning tools, core drills, and grinding wheels.

3. How do I choose the right diamond-tipped tool for my application?

The choice of diamond-tipped tool depends on the material being cut, the cutting operation, the desired cutting speed, the cutting depth, and the expected tool life.

4. How do I maintain diamond-tipped tools?

Diamond-tipped tools require proper maintenance to ensure optimal performance and longevity. This includes cleaning the tools after use, storing them properly, and using appropriate lubricants.

5. Are diamond-tipped tools expensive?

Diamond-tipped tools are generally more expensive than conventional tools due to the use of diamonds. However, their superior performance, longevity, and efficiency can offset the initial cost in the long run.

6. Are diamond-tipped tools environmentally friendly?

Diamond-tipped tools can be considered environmentally friendly due to their extended tool life, which reduces the need for tool replacements and minimizes waste.

Tips for Using Diamond-Tipped Tools

- Use the correct tool for the application. Choosing the wrong tool can lead to poor performance, tool damage, and even accidents.

- Use appropriate lubricants. Lubricants help reduce friction and heat during cutting operations, extending tool life and improving performance.

- Avoid excessive force. Applying excessive force can damage the diamond-tipped tool and reduce its lifespan.

- Clean the tool after use. Cleaning the tool removes debris and prevents corrosion, extending its lifespan.

- Store the tool properly. Store the tool in a dry and clean place to prevent damage and corrosion.

Conclusion

Diamond-tipped tools have revolutionized various industries, offering unmatched precision, durability, and efficiency. Their unique properties, derived from the exceptional hardness and resilience of diamonds, enable them to tackle challenging materials and deliver consistently accurate results. From manufacturing and engineering to construction and scientific research, diamond-tipped tools play a critical role in shaping our world, driving innovation, and advancing technological progress. As we continue to push the boundaries of precision and efficiency, diamond-tipped tools will undoubtedly remain indispensable instruments, ensuring the creation of high-quality products and solutions that meet the demands of a rapidly evolving world.

Closure

Thus, we hope this article has provided valuable insights into The Indelible Mark of Precision: Unveiling the Power of Diamond-Tipped Tools. We appreciate your attention to our article. See you in our next article!