The Precision of Light: A Comprehensive Guide to Laser Soldering in Jewellery

Related Articles: The Precision of Light: A Comprehensive Guide to Laser Soldering in Jewellery

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Precision of Light: A Comprehensive Guide to Laser Soldering in Jewellery. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: The Precision of Light: A Comprehensive Guide to Laser Soldering in Jewellery

- 2 Introduction

- 3 The Precision of Light: A Comprehensive Guide to Laser Soldering in Jewellery

- 3.1 Understanding the Fundamentals of Laser Soldering

- 3.2 Beyond the Basics: Exploring the Different Types of Laser Soldering

- 3.3 Laser Soldering in Action: Applications in the Jewellery Industry

- 3.4 FAQs about Laser Soldering in Jewellery

- 3.5 Tips for Choosing a Laser Soldering Service

- 3.6 Conclusion: The Future of Jewellery Creation

- 4 Closure

The Precision of Light: A Comprehensive Guide to Laser Soldering in Jewellery

In the world of fine craftsmanship, precision is paramount. Jewellery, with its delicate details and intricate designs, demands techniques that can fuse metals flawlessly without compromising the integrity of the piece. Laser soldering has emerged as a revolutionary technique, transforming the landscape of jewellery creation with its unparalleled accuracy, speed, and control.

Understanding the Fundamentals of Laser Soldering

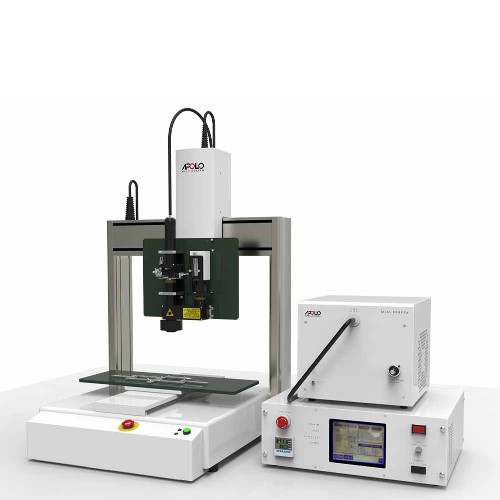

Laser soldering utilizes a focused beam of high-intensity light to generate heat, melting the solder and fusing it to the desired location on the jewellery piece. This process is incredibly precise, allowing for intricate designs and delicate repairs that would be impossible with traditional soldering methods.

The Process in Detail:

- Preparation: The jewellery piece is meticulously cleaned to remove any impurities that could interfere with the soldering process.

- Positioning: The piece is placed on a designated platform, ensuring precise alignment for the laser beam.

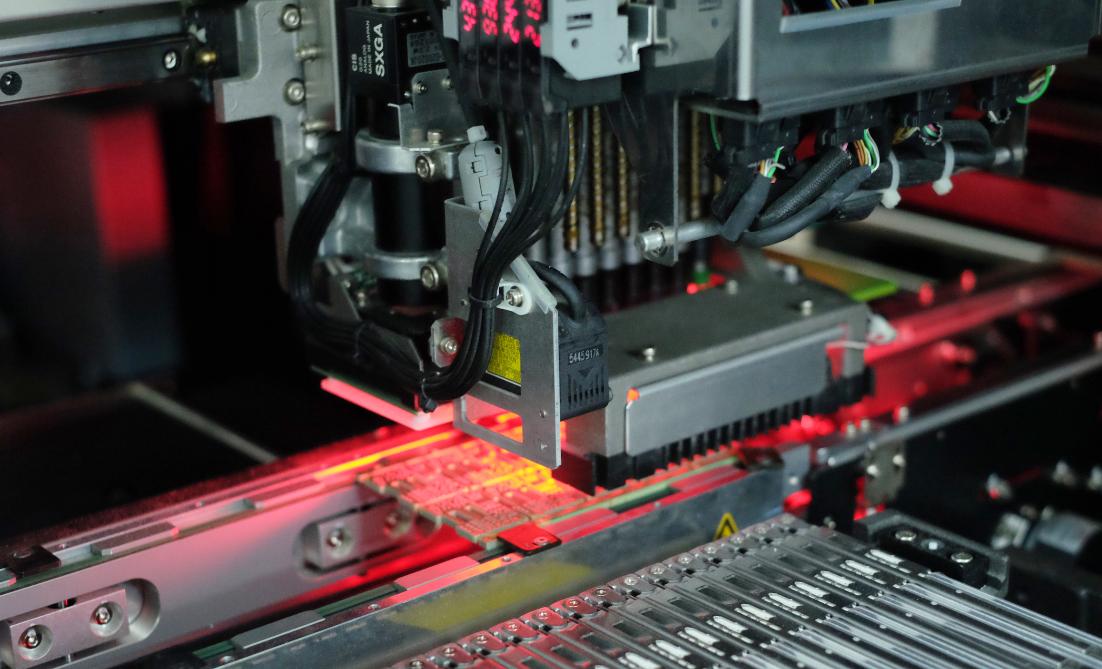

- Laser Application: The laser beam is directed at the designated soldering point, delivering a concentrated burst of heat.

- Soldering: The solder, often in the form of a pre-placed wire or paste, melts and flows into the desired location, creating a strong and durable bond.

- Cooling: The piece is allowed to cool slowly, ensuring a consistent and stable bond.

Laser Soldering: A Revolution in Jewellery Creation

The impact of laser soldering on the jewellery industry is undeniable. It has revolutionized the way jewellery is crafted and repaired, bringing numerous advantages:

- Precision and Control: Laser soldering allows for pinpoint accuracy, minimizing the risk of damaging delicate details and achieving precise placement of solder.

- Minimal Heat Distortion: Unlike traditional soldering, laser soldering focuses heat on the target area, minimizing the risk of heat distortion or damage to the surrounding metal.

- Speed and Efficiency: The laser’s concentrated heat allows for faster soldering times, leading to increased efficiency in production and repair processes.

- Enhanced Durability: Laser soldering creates a strong and durable bond, ensuring the longevity of the jewellery piece.

- Reduced Waste: The precise nature of laser soldering minimizes solder waste, contributing to a more sustainable and environmentally conscious practice.

- Versatility: Laser soldering is compatible with a wide range of metals, including gold, silver, platinum, and even titanium, making it a versatile tool for various jewellery styles.

Beyond the Basics: Exploring the Different Types of Laser Soldering

While the core principle remains the same, laser soldering techniques can be further categorized based on the specific applications:

- Spot Soldering: This method uses a focused laser beam to melt and fuse solder at a specific point, ideal for delicate repairs or attaching small components.

- Line Soldering: A continuous laser beam creates a line of solder, perfect for joining larger pieces or creating intricate designs.

- Surface Soldering: The laser beam is used to melt and flow solder over a larger surface area, ideal for creating seamless joins or adding decorative elements.

Laser Soldering in Action: Applications in the Jewellery Industry

The versatility of laser soldering makes it an invaluable tool across various aspects of jewellery creation:

- New Jewellery Design: Laser soldering allows for intricate designs that would be impossible with traditional methods, pushing the boundaries of artistic expression in jewellery.

- Repairs and Restorations: Laser soldering offers a precise and efficient solution for repairing broken jewellery, restoring its original beauty and functionality.

- Setting Stones: Laser soldering can be used to securely set gemstones, ensuring they are held in place without compromising the integrity of the surrounding metal.

- Customizations and Modifications: Laser soldering enables the creation of unique and personalized jewellery pieces, allowing for modifications and customizations to meet individual preferences.

FAQs about Laser Soldering in Jewellery

Q: Is laser soldering safe for precious metals like gold and platinum?

A: Yes, laser soldering is safe for precious metals. The laser beam focuses its energy precisely on the target area, minimizing the risk of damage or discoloration to the surrounding metal.

Q: Can laser soldering be used on all types of jewellery?

A: While laser soldering is compatible with a wide range of metals, it may not be suitable for all types of jewellery. Factors such as the size, shape, and material of the piece can influence the effectiveness of laser soldering.

Q: How does laser soldering compare to traditional soldering methods?

A: Laser soldering offers several advantages over traditional methods, including greater precision, less heat distortion, and faster processing times. However, traditional soldering might still be preferable for certain types of repairs or for working with larger pieces.

Q: What are the potential drawbacks of laser soldering?

A: While laser soldering offers numerous benefits, it also has some potential drawbacks:

- Initial Investment: The equipment required for laser soldering can be expensive, representing a significant investment for jewellery makers.

- Operator Training: Proper training is crucial for using laser soldering equipment effectively and safely.

Q: Is laser soldering environmentally friendly?

A: Laser soldering contributes to a more sustainable practice by minimizing solder waste and reducing the overall energy consumption compared to traditional methods.

Tips for Choosing a Laser Soldering Service

When choosing a laser soldering service, consider the following factors:

- Experience and Expertise: Look for a service provider with a proven track record in laser soldering jewellery.

- Equipment Quality: Ensure the service provider uses high-quality laser equipment for optimal results.

- Customer Service: Choose a service provider that offers clear communication, prompt responses, and a commitment to customer satisfaction.

- Pricing: Compare pricing from different service providers, ensuring transparency and competitive rates.

Conclusion: The Future of Jewellery Creation

Laser soldering has become an indispensable tool for modern jewellery creation, enabling unparalleled precision, speed, and control. Its ability to handle delicate details, minimize heat distortion, and enhance durability makes it an ideal choice for both new jewellery design and intricate repairs. As the jewellery industry continues to evolve, laser soldering will undoubtedly play an increasingly vital role in shaping the future of fine craftsmanship.

Closure

Thus, we hope this article has provided valuable insights into The Precision of Light: A Comprehensive Guide to Laser Soldering in Jewellery. We thank you for taking the time to read this article. See you in our next article!