The Precision of Personalization: Exploring Laser Engraving Machines in Jewelry Crafting

Related Articles: The Precision of Personalization: Exploring Laser Engraving Machines in Jewelry Crafting

Introduction

With great pleasure, we will explore the intriguing topic related to The Precision of Personalization: Exploring Laser Engraving Machines in Jewelry Crafting. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Precision of Personalization: Exploring Laser Engraving Machines in Jewelry Crafting

In the world of jewelry, personalization holds immense value. It transforms a piece of adornment into a cherished symbol, carrying memories and emotions. Laser engraving machines have emerged as indispensable tools, enabling jewelers to etch intricate designs and meaningful messages onto various materials, adding a unique touch to each creation.

Understanding the Technology:

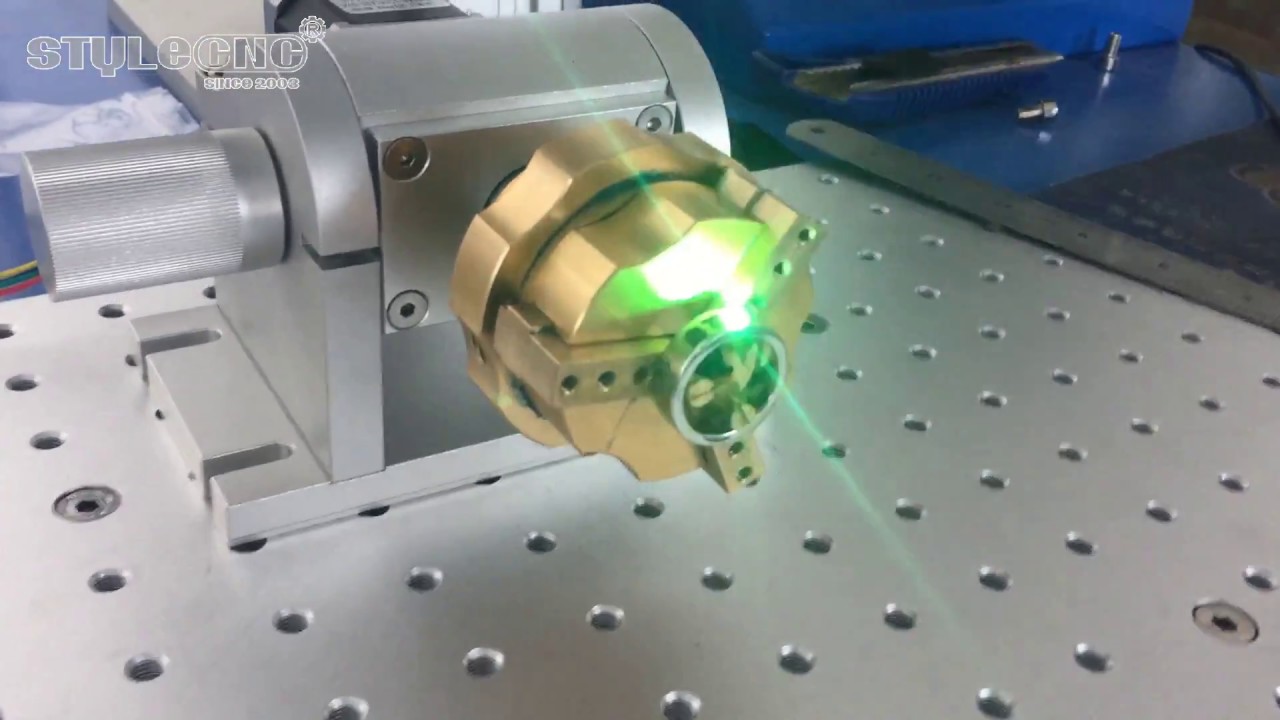

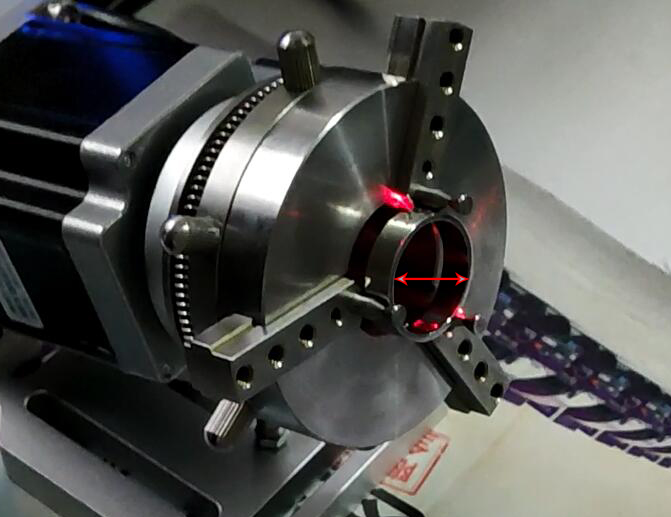

Laser engraving machines utilize a focused beam of light, often from a CO2 or fiber laser, to ablate or mark the surface of a material. This precise and controlled process creates permanent engravings, leaving behind intricate details and fine lines that cannot be achieved through traditional methods. The technology’s versatility allows for engraving on a wide range of materials commonly used in jewelry, including:

- Metals: Gold, silver, platinum, and stainless steel are prime candidates for laser engraving. The process can create elegant designs, intricate patterns, and personalized messages on these lustrous surfaces.

- Precious and Semi-Precious Stones: The ability to engrave on gemstones like diamonds, sapphires, rubies, and emeralds adds a touch of exclusivity and artistic flair to jewelry pieces.

- Wood and Leather: Laser engraving is ideal for crafting unique pendants, charms, and other jewelry accessories from natural materials, enhancing their aesthetic appeal.

- Plastic and Acrylic: These materials offer a wider range of color options and allow for the creation of intricate designs, making them suitable for contemporary jewelry pieces.

Benefits of Laser Engraving in Jewelry Crafting:

-

Unparalleled Precision and Detail: Laser engraving machines offer exceptional precision, allowing jewelers to create incredibly fine details, intricate patterns, and delicate script that would be impossible to achieve manually.

-

Enhanced Personalization: The ability to engrave custom designs, names, dates, or special messages elevates jewelry pieces from mere adornments to cherished keepsakes.

-

Versatility in Materials: Laser engraving technology works on a wide range of materials, opening up a world of creative possibilities for jewelers.

-

Time and Cost Efficiency: Laser engraving machines streamline the engraving process, reducing the time and labor required compared to traditional methods. This translates to cost savings and faster turnaround times.

-

Increased Production Capacity: The automated nature of laser engraving allows for increased production capacity, making it suitable for both small-scale and large-scale jewelry businesses.

-

Enhanced Durability: Laser engraved designs are permanent and resistant to fading or wear, ensuring the lasting beauty and meaning of the jewelry piece.

-

Reduced Risk of Damage: Laser engraving machines minimize the risk of damaging delicate jewelry pieces during the engraving process, ensuring the integrity of the final product.

Types of Laser Engraving Machines for Jewelry:

-

CO2 Laser Engraving Machines: These machines are commonly used for engraving on materials like wood, leather, acrylic, and some metals. They offer a high power output, making them suitable for deep engravings and larger designs.

-

Fiber Laser Engraving Machines: These machines are ideal for engraving on metals, including gold, silver, and platinum. They offer high precision and a smaller beam size, allowing for intricate details and delicate designs.

-

Desktop Laser Engraving Machines: These compact and affordable machines are suitable for small-scale jewelry businesses or hobbyists. They offer basic engraving capabilities and are ideal for engraving smaller jewelry pieces.

Choosing the Right Laser Engraving Machine:

The choice of laser engraving machine depends on factors such as the type of jewelry being crafted, the desired level of detail, and the production volume. Consider these factors:

- Material Compatibility: Ensure the machine is compatible with the materials you plan to engrave.

- Power Output and Beam Size: The power output and beam size determine the depth and precision of the engravings.

- Software and Features: Choose a machine with user-friendly software and features that meet your specific needs.

- Budget: Laser engraving machines come in a range of prices, so set a realistic budget before making a purchase.

FAQs about Laser Engraving Machines in Jewelry:

Q: What is the cost of a laser engraving machine for jewelry?

A: The cost of a laser engraving machine varies widely depending on its features, power output, and brand. Desktop laser engraving machines can range from a few hundred to a few thousand dollars, while industrial-grade machines can cost tens of thousands of dollars.

Q: How long does it take to engrave a piece of jewelry?

A: The engraving time depends on the size and complexity of the design, the material being engraved, and the machine’s power output. Simple designs can be engraved in a few seconds, while intricate designs may take several minutes.

Q: What are the safety precautions to take when using a laser engraving machine?

A: Laser engraving machines emit high-intensity light beams that can be harmful to the eyes. Always wear protective eyewear and follow the manufacturer’s safety guidelines when operating the machine.

Q: Can I engrave any metal with a laser engraving machine?

A: Not all metals are suitable for laser engraving. Some metals, such as titanium and certain alloys, may not be compatible with the laser’s wavelength.

Q: Can I engrave multiple jewelry pieces at the same time?

A: Some laser engraving machines have a larger work area that allows for engraving multiple pieces simultaneously, improving efficiency and production capacity.

Tips for Using a Laser Engraving Machine for Jewelry:

- Clean the surface of the jewelry piece before engraving.

- Use a high-quality laser engraving software for precise design creation and control.

- Calibrate the laser machine regularly to ensure accurate engravings.

- Test the engraving process on a scrap piece of material before engraving the final jewelry piece.

- Store the laser engraving machine in a clean and dry environment to prevent damage.

Conclusion:

Laser engraving machines have revolutionized the jewelry industry, enabling jewelers to create personalized and intricately detailed pieces that resonate with customers. The technology’s precision, versatility, and efficiency make it an invaluable asset for any jewelry business, whether small or large. As technology continues to advance, laser engraving machines will undoubtedly play an even more significant role in shaping the future of jewelry design and craftsmanship.

Closure

Thus, we hope this article has provided valuable insights into The Precision of Personalization: Exploring Laser Engraving Machines in Jewelry Crafting. We hope you find this article informative and beneficial. See you in our next article!